I started building my drone a while ago. I cut many of its parts with my home-made Shapeoko derivative CNC router. I was flying high for a while as work piled up and I decided to put it aside. I now pick it up. I am a little ashamed that it took me so long to get my soldering iron heated up but I reached that crisis point today, with the hope that I will be launching my hexacopter drone on its inaugural flight on this holiday week. This is one of its 6 arms complete with carbon fiber propeller:

Each arm had 9 connections to be soldered. I made it a day and got the rest done:

I now need to get this heavy lifter in the air. I know a bit about Arduino and less about ARDUPilot but I am psyched that I may successfully launch my first homemade drone in the coming days.

Sunday, December 21, 2014

Sunday, June 8, 2014

The Big Fix for My Revolution XL 3D Printer - Using the CNC Router

After several design problems ultimately led to the conversion of my Revolution XL from a pretty good 3D printer to a paperweight, I stared at it for a time contemplating how I could resurrect it, while turning it into the sort of machine I wish I had bought originally. Its shortcomings became increasingly apparent with time:

- Terrible Z-homing repeatability

- Hot end heater wires inevitably fail due to motion/metal fatigue at the point of the last nanolink before the wires emerge from the nanolink cable management.

- When the heater wires fail on the hot end, the extruder gearbox starts to slip, which wears down its gears.

- When the gears begin to fail, a clicking sound is substituted for extrusion resulting in a failed print

I loved many aspects of the RXL. It was well designed, for the most part. It is extremely rigid and the doubling of the motors was a great touch. So my mission became to fix this otherwise good but currently useless machine.

I began with the extruder. It needed replacement. I decided on a Bowden setup, and because I have wasted so much time over the years on bad extruders and hot-ends, I decided to splurge: I bought Micron3dp.com's extruder and hot-end together for $300 on eBay. It struck me as overpriced but it was an irresistably beautiful piece of engineering. But to make this work, I would have a lot of work to do. It was unfortunate that my silenced 3D-printer was, at-this-point, unable to print its own replacement parts but fortunately, My CNC router in the basement was still functional and ready to cut parts out of 1/8" aluminum plate.

And so my adventure began.

I started off designing (and machining) the new extruder mount. It turned out that I had to redesign and re-machine 2 of the 5 required parts several times to make them work. A lot of aluminum plate went into my trials and errors:

Part 1: The hot-end mount and clamp

It took 4 tries before I got the hot-end mount done right:

I started off designing (and machining) the new extruder mount. It turned out that I had to redesign and re-machine 2 of the 5 required parts several times to make them work. A lot of aluminum plate went into my trials and errors:

It took 4 tries before I got the hot-end mount done right:

The mounting clamp was simpler:

Together, they allow for two of these hot ends to be mounted to the RXL. I am starting with a single extruder/hot-end but it would be a silly waste of time doing all this without thinking of the future. I started by removing the old extruder and mounting hardware

Next, I screwed in the mounting clamp:

Then the extruder mount (this was before the redesigns but you get the idea

And so I was able to screw in the new hot end:

To finish this up, I needed to put some work into the hot-end as well. I replaced its 12v fan with a 24v fan. I also had to extend all wires and tuck them all into a neat braided sleeving, suggested to me by MacAttak.

Part 2: The Bowden Extruder Mount

My design:

Like the mounting plate, I had to design and machine four iterations before I got it right:

Now folded further under the heat of a MAP gas torch:

Now mounted on the X axis with M3 x 10 screws and glued to the X-belt:

Now altogether with the Bowden tube installed:

Here it is, finally in action:

Together, they allow for two of these hot ends to be mounted to the RXL. I am starting with a single extruder/hot-end but it would be a silly waste of time doing all this without thinking of the future. I started by removing the old extruder and mounting hardware

Next, I screwed in the mounting clamp:

Then the extruder mount (this was before the redesigns but you get the idea

And so I was able to screw in the new hot end:

To finish this up, I needed to put some work into the hot-end as well. I replaced its 12v fan with a 24v fan. I also had to extend all wires and tuck them all into a neat braided sleeving, suggested to me by MacAttak.

Part 2: The Bowden Extruder Mount

My design:

I removed 2 screws, replaced them with longer ones, and attached this mount to the rear-left-top corner so that the result looked like this:

The wiring was a pain. I used crimpable, self-soldering butts to connect the heater wires and solder for the rest. All connections were covered with heat-shrink tubing:

Finally, everything was covered in bigger heat-shrink tubing:

Part 3: The X-belt connector/X-end-stop trigger

This was the hardest item that I made but the item that I am most proud of designing. It needed to perform two functions -- to be glueable to the X-axis belt and to trigger the X end-stop. This was the first project where I needed to score, heat and fold metal, namely 1/8" 6061 aluminum plate. This was the final CAD design:

Now folded further under the heat of a MAP gas torch:

Now mounted on the X axis with M3 x 10 screws and glued to the X-belt:

Now altogether with the Bowden tube installed:

Here it is, finally in action:

For those of you interested in making the same modification to your RXL, I offer the following files free for use with the stipulation that you attribute the files and design to me and this blog. The CAD/CAM files were designed with CamBam, a great and affordable Windows software that I have grown increasingly fond of and that I used to create these parts. The native CamBam CAD/CAM file and DXF file can be found here.

So far, so good. Now I need to figure out how to decrease stringing on such a Bowden setup. I am confident that the Ultimaker community has blazed a sufficient trail for me to follow that I am not too worried.

Sunday, May 25, 2014

QU-BD Revolution XL Review Part 4

After a bit of a hiatus from blogging, I decided to return with this final review of the QU-BD Revolution XL that was delivered to me in August of 2013. At this point it is no longer operational, pending some necessary upgrades. Before I launch into the full list of problems and design flaws of the RXL, it is only fair that I give mention to its positive attributes, chief among them - build quality. It's frame is well-engineered, its rods are well-polished and it was obvious that QU-BD set out to make a world class 3D printer. That said, here were the problems that plagued it and more that eventually turned it into a very heavy paperweight:

- Loose Bed: The volcanic glass bed does not fit snugly on the tray holding it. There is about a 2mm gap in both directions. If you are printing slowly enough to limit vibration, this issue is of no consequence because of the weight of the bed but if you step up the speed (the RXL was arguably built for speed), vibrations will move the bed slightly mid-print, resulting in a failed print.

- Z-axis homing: Within a couple of weeks of use, Z-axis homing repeatability became a problem and the problem increased from there. A couple of factors were to blame: the position and quality of the Z-axis endstop. The problem with its position is that it was located on the side of the unit whereas the Z-axis leadscrews were toward the center. Fellow RXL owner Illuminarti came up with and posted an inventive solution to this problem, which I have adopted. The second problem, that of the quality of the switch itself came close to causing the machine to damage itself. The switch would remain in the opened position despite being pushed all the way in. Fortunately, my unit unlike those of others who had this problem, was never damaged.

- X-truder: This was supposed to be one of the big selling points of the RXL. It is a small extruder with counter-rotating gears that is still advertised by them as "the best extruder on the market". After 9 months with it, I would beg to differ. My first one began to fail a couple of months after I received the printer. At one point it decided to stop extruding and to instead start clicking. QU-BD was good about getting me a replacement and asking me for the return of my old one for analysis but claimed to have solved the problem. A few months later the same problem occurred again, but the second time would bring me no customer service solution -- but more on QU-BD's customer service later.

One of the big consequence of the X-truder's compact size was that the cold barrel leading to the hot-end had no cooling fins. This was fine if you wanted to print a vase or other parts not requiring retraction but anything but the slightest of retraction would inevitably lead to a clogged nozzle.

The biggest problem with the X-truder was that the tension of the gears could not be adjusted. Practically speaking, this meant that I could never get it to extrude Taulman's T-Glase, one of the more popular filaments, because the gears would slip against that filament's smooth surface. I could get smooth PLA to print but only at painfully slow speeds.

In the end, I, like others, had to resort to third party extruder/hot end replacements. I will detail my upgrade process in a future post. - Extruder carriage nanolinks: I can see why QU-BD thought the use of Nanolinks cable management for managing the wires going to the extruder and hot end was a good idea. It did keep things looking clean. The flaw was that the carriage moves back and forth so quickly that the nanolinks' restriction of the motion of the cables to one direction would inevitably result in metal fatigue occurring in the heater wires. This has happened to several RXL users, myself included. This was in fact the flaw that finally silenced my RXL.

The biggest flaw with the RXL lies not as much with the printer itself but with QU-BD's customer service. Recently, they changed their domain name/company name from QU-BD.com to QuintessencialUniversalBuildingDevice.com. I suspect that this move was one way to deal with the online customer backlash that Googling "QU-BD" will reveal. There is nothing like re-branding! Unfortunately, the new multi-syllabic name does nothing to address their festering customer service problems. As an example, I opened a case with them the moment when my extruder and cable failed. Their rep wrote back to me within 10 days, telling me that they would send me a new improved extruder that had been improved upon. That was 4/6/14. On 4/15, I sent a message asking if it had in fact gone out. Nothing. On 4/28, I wrote again. The rep did get back to me that day and said "Sorry for the delay. We ran out of the extruder stepper motors but just got a new batch in. I will make sure that it goes out today."

That was one month ago. Still nothing. My subsequent inquiry on 5/8 resulted in no reply. I give up.

That was one month ago. Still nothing. My subsequent inquiry on 5/8 resulted in no reply. I give up.

An upgrade of the extruder/hot-end to a modern, all metal design will likely put many of these issues to rest and result in a greatly improved printer. I have chosen to go with a Bowden version of this high-quality extruder/hot-end pair from Micron3dp. When I am finished upgrading the RXL, it will no longer be the same machine. I will make it work and and I have no doubt it will be greatly improved, but in retrospect, I wish that I had simply bought an Ultimaker. Had I done so, more of my writing would have been 3D printer use rather than 3D printer fixing.

Saturday, November 23, 2013

Shapeoko CNC router Electronics Upgrade - Part 2: Finishing the Enclosure and Electronics Mounting Parts

Preparing the Enclosure for the Electronics

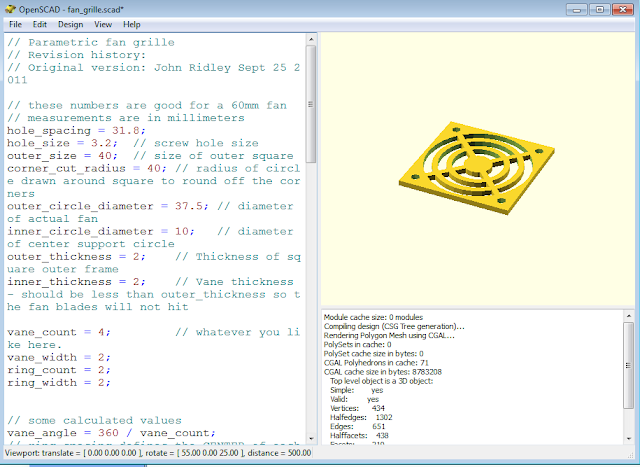

I had to print three parts to get everything to fit snugly inside my new enclosure. First, I needed a mount for my Raspberry Pi. I found an appropriate one on Thingiverse: http://www.thingiverse.com/thing:37889 .Next I needed an Arduino Uno/grbl mount: http://www.thingiverse.com/thing:33327. Finally, I needed a fan grille, but I could not find any out there that I could download and print directly. I then came across this wonderful parametric fan grille that one could download, configure and print, brilliantly written by John Ridley a couple of years ago.

I downloaded the scad file, opened it using OpenSCAD, "The Programmers Solid 3D CAD Modeller" (free). All I had to do was take some measurements with my caliper, enter all the parameters the program required and, voila! a perfect fan grille, perfectly sized, ready to be printed:

In a pleasant surprise, printing went off without a hitch. Here are the printed parts:

The next step was to mount the emergency-stop button, fan and fan grille to the top of the box:

I then used screws and trapped nuts to put the rest of the enclosure together.

With the enclosure and mounting parts complete, I am ready for the next step: Turn the Raspberry Pi into a dedicated gcode sender that can be wirelessly remote-controlled from any computer or tablet in the house.

Tuesday, November 19, 2013

Shapeoko CNC router Electronics Upgrade - Part 1: New Enclosure

Right now, my Shapeoko variant router works fine. There are only a couple of issues that need to be resolved. The main issue is that I need to use a laptop (that I would rather use elsewhere) to act as a g-code sender. My thought is that the perfect scenario would be to replace that laptop with a Raspberry Pi running a g-code sender and a XRDP allowing me to remote into it over Wifi from any PC or tablet in the house. If that scenario could work, I would be able to create an enclosure housing the Arduino Uno/grbl shield together with the Raspberry Pi. I could then also include a cooling fan and a sorely-needed emergency-stop switch (until now, I have been using the power strip switch as a poor man's e-stop).

The Enclosure

I decided to mill my rectangular enclosure out of 1/4" plywood. I want all parts to have finger joints and T-slots so that I can use screws and nuts to lock the enclosure together. After a bit of research on how to do this I found a great, free T-slot Boxmaker extension to the also-great and free Inkscape design software that allows you to specify the box's parameters before it creates the box design for you. These were my parameters for the enclosure:

So I reset the system to 0, 0 and manually moved the bit to this point that Cambam said was at 100mm x 83mm:

The Enclosure

I decided to mill my rectangular enclosure out of 1/4" plywood. I want all parts to have finger joints and T-slots so that I can use screws and nuts to lock the enclosure together. After a bit of research on how to do this I found a great, free T-slot Boxmaker extension to the also-great and free Inkscape design software that allows you to specify the box's parameters before it creates the box design for you. These were my parameters for the enclosure:

The result was this:

I then saved it as a DXF file and opened it in my preferred CNC software: CamBam. The following steps were to rotate the parts (on my CNC router, my Y is longer than my X axis), delete unnecessary screw holes and T-slots, add holes for the fan and E-stop switch and wire and ventilation slots to the end pieces. The final design for the enclosure looked like this:

So with chest full of air and heart full of pride, I start my cut... Only to fail. For some reason, my computer and grbl controller disconnect well into the cut. I needed to re-zero the tool, which of course means finding that zero. When it failed, it had already cut the following in red:

I then instructed X to go to -100 and Y to go to - 83 and, voila: the old zero was found. I now once again reset the controller so that the new 0, 0 was recognized, disabled the previously-completed T-slot cuts, regenerated the gcode and got it to continue where it left off.

Now, I will try to avoid boring you with the intervening failure that took so much of my time. Sufficed to say that my machine was failing when trying to drill small holes. It turned out that it was choking on the fact that these holes were made from thousands of useless lines of code. Once I simplified those holes by replacing them with circles and regenerated gcode, all worked well.

Once everything was set, I finally had my machine cut the enclosure parts from 1/4" Birch plywood.

This was the result:

I noticed one problem: The E-stop switch will not fit a 1/4" thick surface, so I will need to consider a fix to this. Otherwise, I am pleased with my first computer-generated finger-joint box.

On my next post, I intend to detail how to configure a Raspberry Pi to be a remote-controller for an Arduino/grbl-based CNC router such as Shapeoko.

Wednesday, November 6, 2013

Building a hexacopter drone with the help of CNC routing and 3D printing

After building a couple of 3D printers and a CNC router, I found that many of my friends would quite reasonably inquire as to what I actually make using these machines. For a long time my reply was that I used them mostly to make 3D printer and CNC router parts, after a while allowing me to come to the realization that my obsession with these machines was, quite literally, feeding itself.

All that changes with my latest project: to build a heavy-lifting, full-featured aerial hexacopter drone with as many parts as possible being CNC routed or 3D printed in-house.

The first thing that I had to settle on was what design to use. I had been following the progress of many projects at DIY Drones. One of their very active participants, Jeremy Guillory, published this blog post describing cutting a bunch of hexacopter frame parts out of Lexan (polycarbonate) using a water jet. He also supplied the CAD DXF file that I could use to make those same parts with my CNC router.

The next step was to figure out what material to use. People have been building multi-rotors out of almost every light/strong material imaginable. At the Holy Grail high end is of course, carbon fiber. But the cost is very high and if I mess up a cut, I waste a lot of money. I could have also done it in fiberglass or Aluminum. In the end, I was persuaded by a fellow I met at this year's NYC Makerfaire that I should use a material called Dibond. Dibond is a composite material consisting of a polymer sandwiched between two super-thin sheets of Aluminum. It is light, yet strong and rigid. It also has some helpful vibration dampening qualities. Best of all, it happens to be inexpensive. I bought 5 1/8" Dibond sheets for about $10 each, shipping included. Cutting all the parts required 1 and a half. I had to kill the job at one point when an inadequately-secured part got sucked-in by the bit but I was able to zero out the CNC machine and continue.

The Aluminum arms can be acquired quite inexpensively from HobbyKing.com ($0.88 each!).

My goal, beyond documenting this build is to leave my fellow makers with instructions to build their own full-featured aerial robot at the lowest possible cost.

Stay tuned for more shortly.

All that changes with my latest project: to build a heavy-lifting, full-featured aerial hexacopter drone with as many parts as possible being CNC routed or 3D printed in-house.

The first thing that I had to settle on was what design to use. I had been following the progress of many projects at DIY Drones. One of their very active participants, Jeremy Guillory, published this blog post describing cutting a bunch of hexacopter frame parts out of Lexan (polycarbonate) using a water jet. He also supplied the CAD DXF file that I could use to make those same parts with my CNC router.

The next step was to figure out what material to use. People have been building multi-rotors out of almost every light/strong material imaginable. At the Holy Grail high end is of course, carbon fiber. But the cost is very high and if I mess up a cut, I waste a lot of money. I could have also done it in fiberglass or Aluminum. In the end, I was persuaded by a fellow I met at this year's NYC Makerfaire that I should use a material called Dibond. Dibond is a composite material consisting of a polymer sandwiched between two super-thin sheets of Aluminum. It is light, yet strong and rigid. It also has some helpful vibration dampening qualities. Best of all, it happens to be inexpensive. I bought 5 1/8" Dibond sheets for about $10 each, shipping included. Cutting all the parts required 1 and a half. I had to kill the job at one point when an inadequately-secured part got sucked-in by the bit but I was able to zero out the CNC machine and continue.

The Aluminum arms can be acquired quite inexpensively from HobbyKing.com ($0.88 each!).

My goal, beyond documenting this build is to leave my fellow makers with instructions to build their own full-featured aerial robot at the lowest possible cost.

Stay tuned for more shortly.

Friday, October 4, 2013

More Revolution XL successes and foibles

I spent a lot of time trying to figure out how best to tune my settings to create various objects. For example, printing a vase is a simple matter. No retraction is required and no stringing can happen. Other parts can be more challenging. Probably one of the most challenging prints is a model of the Eiffel Tower, something that I aspire to print correctly soon.

My 3D printing adventures were interrupted by a failure of my X-truder, one of the more innovative features of the RXL. Nathan, head engineer at QU-BD sent me a replacement and I wired it in and sent him back the broken one. To my dismay, when I tried it out, I saw that the extruder fan was not working. I ran a continuity test that ruled out a problem with the cable and surmised that the problem had to be with the fan itself. I ruled out a polarity problem because I presumed that the fan would just spin the wrong way. As it happened, I had a replacement fan on hand (intended for another project) and so I disconnected the non-working one (which I prematurely dissected) and replaced it with the new one. To my frustration and astonishment, the new fan did not run. Now, totally confused, I reversed the polarity of this DC fan and voila! it worked! Even Nathan at QU-BD was stumped. He later told me that he tried to reverse polarity on several fans in the workshop. Some spun backwards, some did nothing.

So I was back up and running -- that is until my next self-induced mishap. Noticing that a certain print was going to go on longer that my filament spool, I devised to wait right until the last of the old filament got sucked down through the extruder and then I would immediately feed the new filament through. This did not work out as planned. The old filament became so lodged in the extruder that I had to disassemble it to get the filament out.

Once everything was back together, I made a personal vow never to try such a dopey move again. My next foible was unexpected. I assumed that scaling an STL file in Slic3r would be a simple matter. It seems to be a bug with Slic3r itself. Here is the original Koch Snowflake vase next to a 2X scaled version:

The one on the left came out perfectly but the one on the right had holes and imperfections around its widest part:

At first I thought it was a printing fluke, but it happened a second time. I will need to research this problem.

The only other new thing that I tried was a new type of filament, namely Taulman 645 Nylon. It really is quite amazing. It is both flexible and incredibly strong. Here is the same vase being printed in Nylon:

Now, onto the Eiffel Tower!

My 3D printing adventures were interrupted by a failure of my X-truder, one of the more innovative features of the RXL. Nathan, head engineer at QU-BD sent me a replacement and I wired it in and sent him back the broken one. To my dismay, when I tried it out, I saw that the extruder fan was not working. I ran a continuity test that ruled out a problem with the cable and surmised that the problem had to be with the fan itself. I ruled out a polarity problem because I presumed that the fan would just spin the wrong way. As it happened, I had a replacement fan on hand (intended for another project) and so I disconnected the non-working one (which I prematurely dissected) and replaced it with the new one. To my frustration and astonishment, the new fan did not run. Now, totally confused, I reversed the polarity of this DC fan and voila! it worked! Even Nathan at QU-BD was stumped. He later told me that he tried to reverse polarity on several fans in the workshop. Some spun backwards, some did nothing.

So I was back up and running -- that is until my next self-induced mishap. Noticing that a certain print was going to go on longer that my filament spool, I devised to wait right until the last of the old filament got sucked down through the extruder and then I would immediately feed the new filament through. This did not work out as planned. The old filament became so lodged in the extruder that I had to disassemble it to get the filament out.

Once everything was back together, I made a personal vow never to try such a dopey move again. My next foible was unexpected. I assumed that scaling an STL file in Slic3r would be a simple matter. It seems to be a bug with Slic3r itself. Here is the original Koch Snowflake vase next to a 2X scaled version:

The one on the left came out perfectly but the one on the right had holes and imperfections around its widest part:

At first I thought it was a printing fluke, but it happened a second time. I will need to research this problem.

The only other new thing that I tried was a new type of filament, namely Taulman 645 Nylon. It really is quite amazing. It is both flexible and incredibly strong. Here is the same vase being printed in Nylon:

The resulting printed part is very resilient as you can see here:

Now, onto the Eiffel Tower!

Subscribe to:

Posts (Atom)